Posted: 15th July, 2024

By Leigh Hackett

We decided to avoid these pathways conscious of the “food or fuel” conflict and the risk of increased carbon emissions associated with indirect-land-use-change including through agricultural displacement.

Well what about Fischer Tropsch technology?” Again a reasonable question as it’s been around for a long time. Here we were put off by the lack of selectivity to SAF, plus the need for additional back-end hydrocracking to increase yields.

We wanted a technology that maximised the conversion of valuable and sometimes hard won carbon into our product i.e. ultra high yield. We wanted high energetic efficiency across the value chain from wire to wing. And we wanted a scalable technology.

The methanol-to-jet route allows us to minimise carbon losses along the way and retain a high level of energy in the final product. To that we have added ultra-high selectivity to maximise SAF production which is all to the benefit of the specific cost of production keeping it affordable.

Finally, and very importantly, we do all of this to minimise GHG emissions from aviation – and to reduce the sector’s contribution to global heating and climate change.

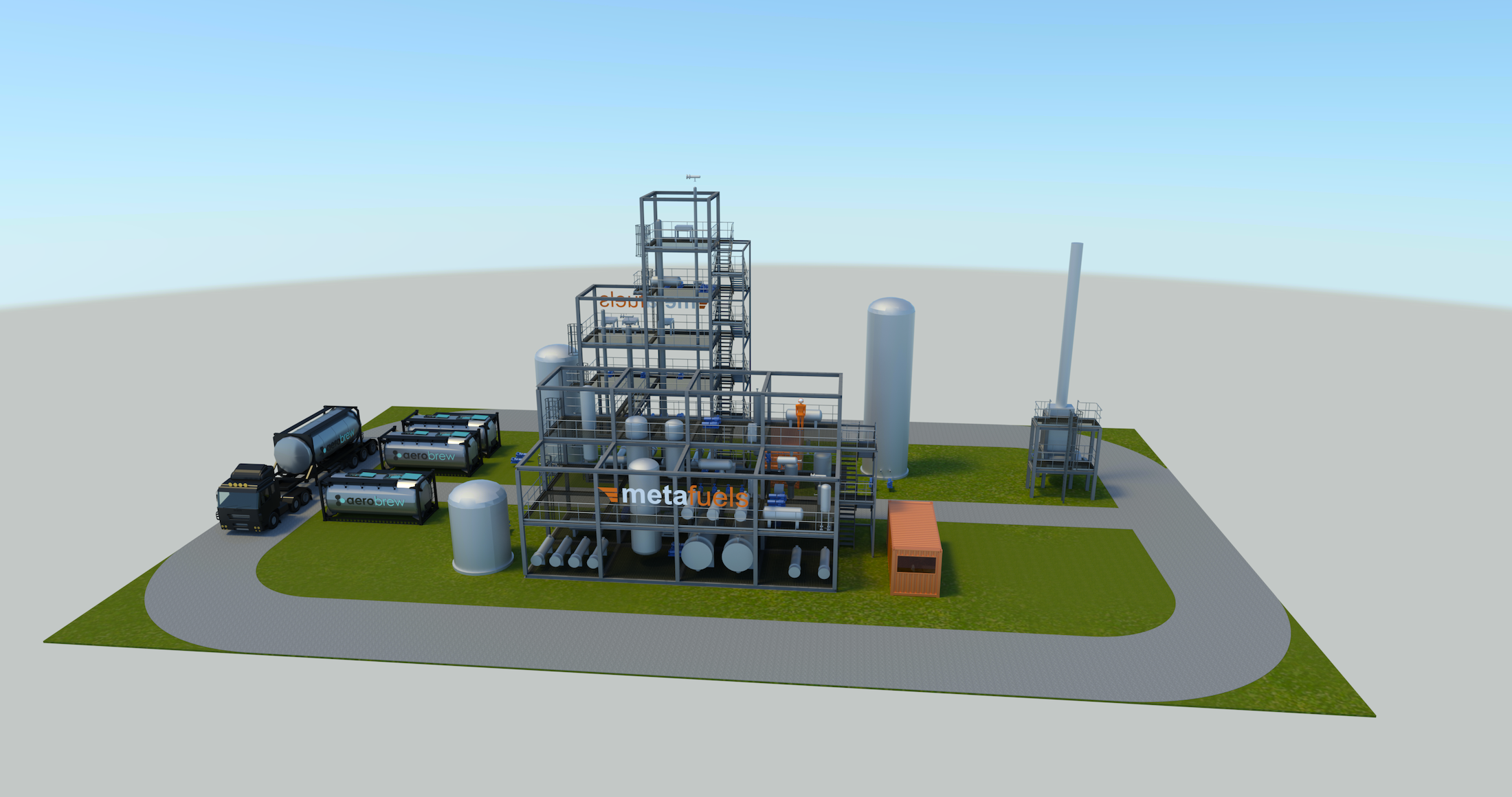

On this score, as an e-SAF route we can achieve very low LCA emissions of up to 90% less than conventional fossil based jet fuel. So MtJ ticked all the boxes for us and led us on the pathway to developing our scalable aerobrew process.

Back to Knowledge Base