)

Metafuels’ three founders have worked together in the energy sector for decades and share an ambition to develop new and affordable sustainable technology solutions.

Meet the team)

Introducing aerobrew, a new route to large-scale production of e-SAF.

If we’re to reduce our carbon footprint and help the aviation industry reach net zero emissions by 2050, Sustainable Aviation Fuel (SAF) will be key.

That’s why Metafuels, working together with the world renowned Paul Scherrer Institut have developed a new concept – aerobrew, a proprietary technology to convert green methanol to SAF. Our pioneering approach is ready to help airlines continue offering affordable air travel for people looking to reduce their carbon footprint, whilst also making the global transportation of goods by air more viable.

Learn about the aerobrew process)

What are the key advantages of aerobrew SAF?

aerobrew technology provides a route to large-scale production of so-called e-SAF, with high selectivity and yields, overcoming the scale up challenges and high costs of alternative routes primarily based on Fischer-Tropsch technology. This leads to attractive project economics and cost leadership.

)

aerobrew is also compatible with the biogenic route whereby green methanol is derived from renewable and sustainable cellulosic biomass (wood, miscanthus, etc.) avoiding the need for feedstocks that compete with the food chain.

What is the global market for SAF?

(USD)

(USD)

)

The IEA, under its net zero scenario (May 2021), projects that 75% of the jet fuel market will be SAF by 2050. This represents around 300 billion litres per annum.

)

Airlines are already looking to increase their usage of SAF thanks to new legislation and a consumer base keen to reduce their own carbon footprints. The aerobrew process is expected to play a key role in meeting the demand, with the ambition to enable fuel manufacturers produce affordable SAF at-scale.

The aerobrew processThe aerobrew process,

a new route to e-SAF production.

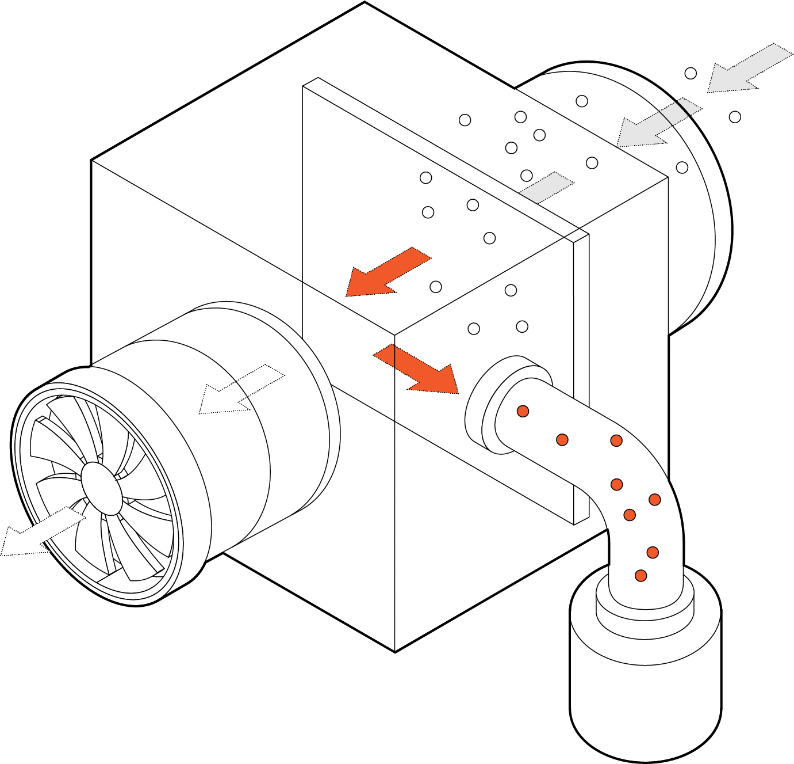

Harnessing CO2 and H2

is recovered through

direct air capture

(and biogenic methods))

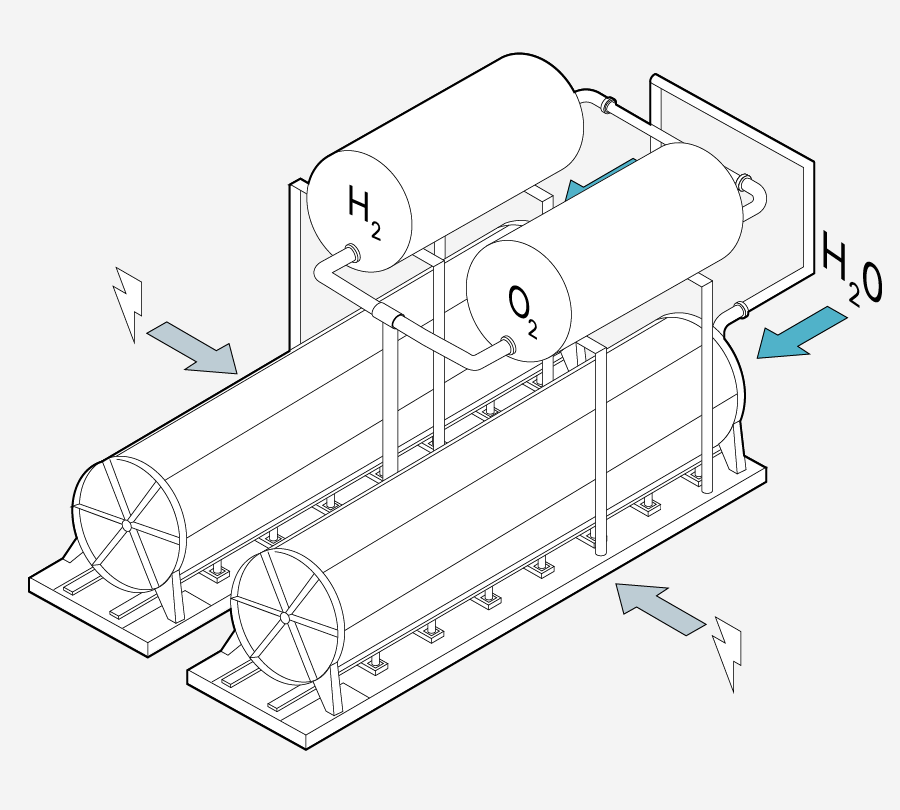

Green H2 can be generated from

water electrolysis

)

)

driven by renewable electricity

These basic elements are then processed into

green methanol

which undergoes our aerobrew process

and translates into

Sustainable Aviation Fuel

)

)